When it comes to compressed air systems, businesses in Perth and across regional WA often find themselves deciding between two main types of compressors: piston and screw. Both have distinct advantages, but the right choice depends on your application, duty cycle, and long-term operating costs. Selecting the wrong type can lead to higher expenses, downtime, and reduced efficiency—so it pays to understand the differences.

Piston Compressors – Where They Work Best

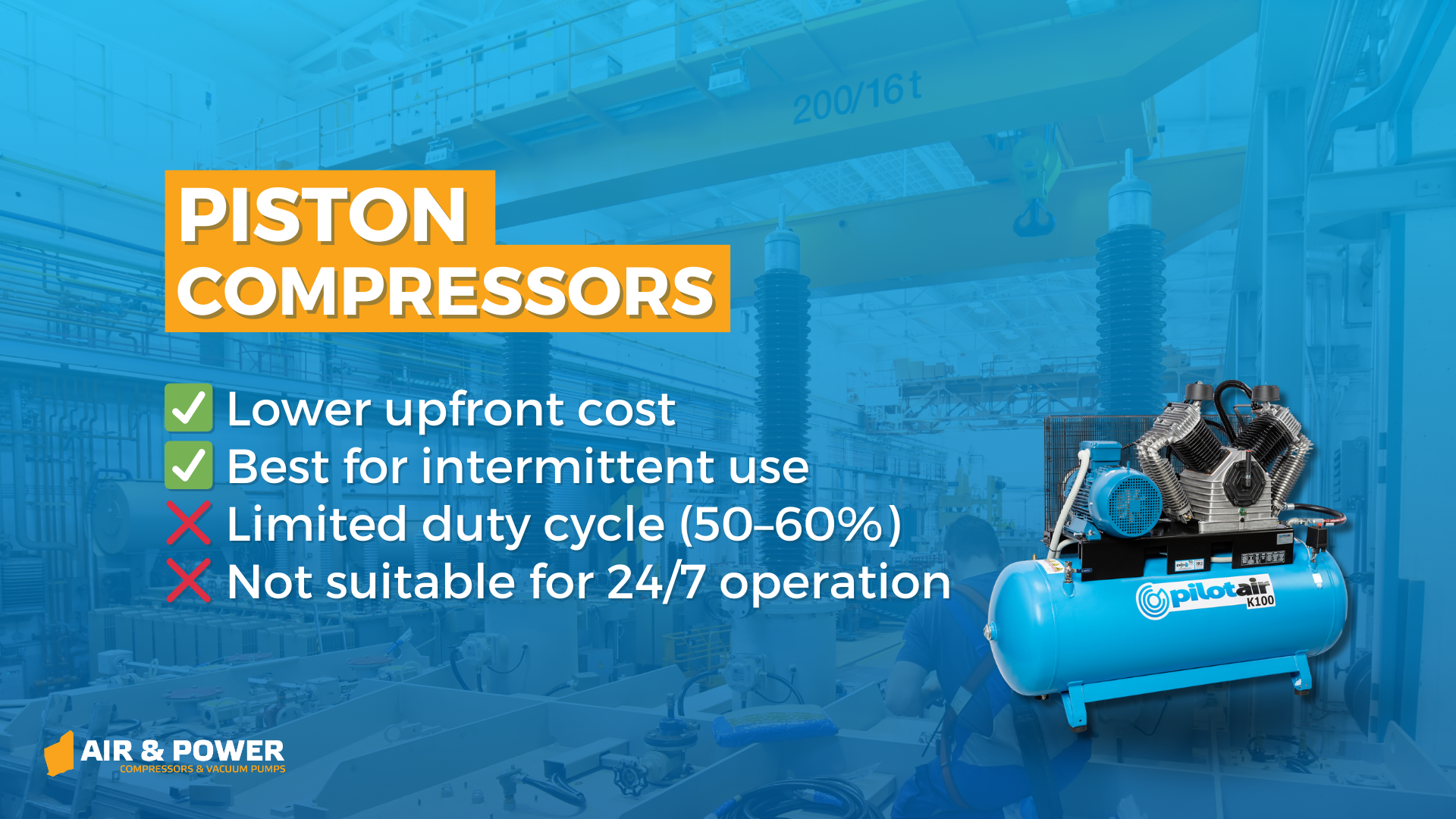

Piston compressors are a popular choice for smaller operations and light-duty applications. They are generally more affordable upfront and are well suited to intermittent use. Workshops, automotive garages, and small factories in Perth often rely on piston compressors because they deliver reliable air power without the higher initial investment of a screw system.

However, piston compressors are not designed for continuous duty. Most models have a duty cycle of around 50–60%, meaning they should only run for about 30–35 minutes of every hour before resting. Heavy-duty models may reach a 75% duty cycle, but running them non-stop risks overheating, faster wear, and reduced service life. For operators who only require air on demand, they remain a cost-effective and practical solution.

Screw Compressors – Where They Excel

Screw compressors are designed for larger operations with high and continuous air demand. They provide a steady air supply, operate more quietly, and generate less heat compared to piston models. Over time, their energy efficiency and durability often outweigh the higher upfront cost.

In regional WA, industries such as mining, agriculture, and heavy manufacturing rely heavily on screw compressors. They are engineered to run 24/7, making them a more reliable choice for demanding environments where downtime is not an option.

When to Switch from Piston to Screw

Many businesses begin with piston compressors but eventually outgrow them as demand increases. Signs that it may be time to upgrade include:

- Frequent downtime or rising maintenance costs

- Energy bills climbing due to inefficiencies

- Expansion from a small-scale workshop into larger production or industrial operations

- Needing longer run times than a piston compressor can safely deliver

Making the switch to a screw compressor at the right time ensures your system can handle demand without compromising productivity.

Choosing the Wrong Compressor

Selecting the wrong type of compressor can have serious consequences. If you rely on a piston compressor for continuous heavy-duty use, you risk frequent breakdowns, costly downtime, and reduced equipment lifespan. On the other hand, investing in a screw compressor for light, intermittent tasks can mean unnecessary upfront costs without a strong return on investment.

Getting the decision right ensures your operation runs efficiently, safely, and cost-effectively—something that’s critical for both Perth workshops and regional industries where support may not always be close at hand.

Why Work With Air & Power?

Air & Power has extensive experience supplying, installing, and servicing both piston and screw compressors across Perth and regional WA. Our team can help you determine which system is the right fit for your needs, ensuring you avoid the costly pitfalls of the wrong choice. We also provide ongoing support, servicing, and spare parts to keep your equipment operating at peak performance.

- Contact us today for expert advice on piston and screw compressors.

- Explore our range of Pilot Air compressors.

- Learn more about our servicing and repair solutions to keep your system running smoothly.